At Machine Software, we design control systems that prioritise both engineering precision and operational usability. Our approach combines modern software architecture with intuitive user interface design, ensuring that your systems are not only powerful but also easy to understand, operate, and maintain.

We leverage contemporary frameworks and UX principles to create operator interfaces that are clean, consistent, and purpose-driven — reducing cognitive load and minimizing the chance of error. Whether it's real-time diagnostics, dynamic visualisation of process states, or system overrides, every function is engineered for clarity and responsiveness.

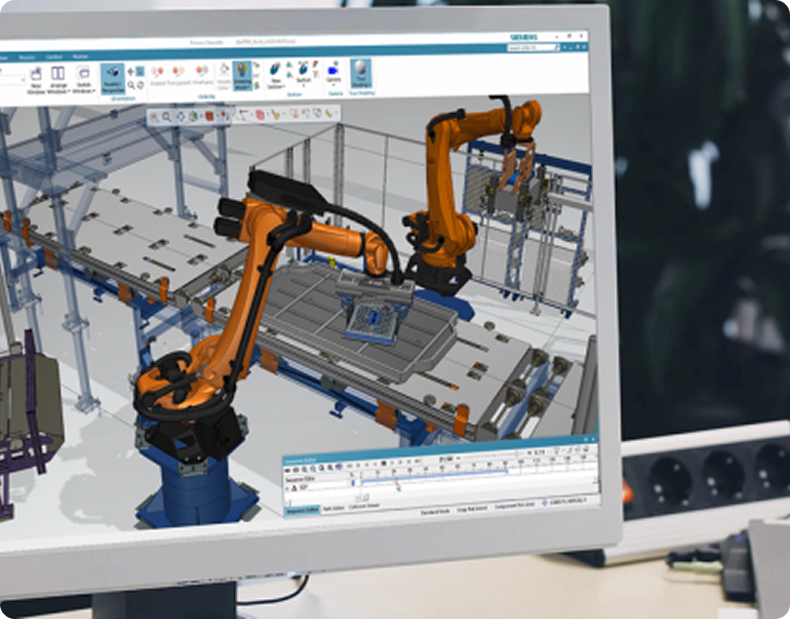

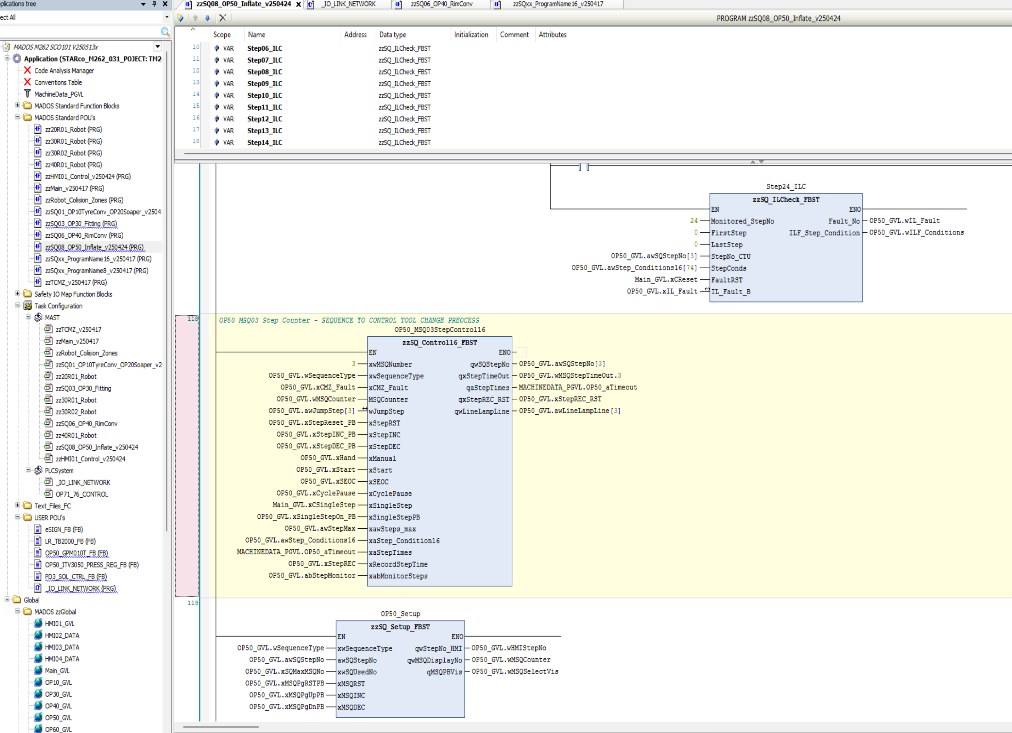

Behind the interface, our systems are built on modular, scalable platforms that integrate seamlessly with existing PLCs, SCADA systems, and industrial protocols. This means you get advanced functionality without compromising compatibility or requiring complete infrastructure overhauls.

We also emphasise maintainability and flexibility. Engineers can easily update workflows, modify control logic, or deploy changes without introducing system instability. This translates to faster commissioning, reduced downtime, and lower total cost of ownership over the lifecycle of your equipment.

With Machine Software, your control systems become assets — not obstacles — to operational excellence.